Dear Reader: This is the first of what I hope will not be the last of this type. Not an interview. More like a podcast in writing. I state a thesis, Josh Poertner (Silca, Marginal Gains Podcast) replies; I reply; Josh finishes. We do this over email. With any luck I 'll prevail upon Josh to engage with me here, in similar fashion, on future topics.

Dan writes: Josh, there is probably very little upon which you and I disagree but I know we are not sympatico on rims with hookless beads. To recap for the reader, this is in the context of road tubeless systems and my reporting is that the majority – between two-thirds and 80 percent – of road and triathlon pros at the highest levels are now on tubeless systems, whether by choice or by sponsor obligation. My sense is that tubeless use is by choice, and that use-by-sponsor-obligation becomes a thing with hookless. The big disagreement now is on rim style and the rap on hookless is that brands are moving to this because of cost and ease of manufacture, while taking away the ability to ride a higher pressure and delivering no substantive value in return. I am less cynical. I’ve put thousands of miles on hookless systems and have not found a downside in the context of my own riding where – for example – I never ride a tire narrower than 27mm. In fact, my own unresolved tech question isn’t hooked or hookless – I’m all in on hookless – but whether or not the wheel needs to have a bead lock on the rim shelf.

But there is no opinion you hold, or stipulation you make, that I don’t take ultra-seriously. In fact, over the past 2 weeks both you and Xavier Disley – of Aerocoach – have been negative on hookless beads in discussions with me and any time I’m in need of guidance on things-that-roll it’s like a lyric from that song American Pie: “The three men I admire most, the Father, Son and the Holy Ghost, took the last train to the coast.” You and Xavier are among the “three men I admire most” on this topic and I’m batting oh-for-two on hookless. I have technical arguments and a lot of miles on this tech, nevertheless, did I miss the last train for the coast and am pedaling my hookless rims on the road to nowhere?

Josh writes: I think your position here fits well with your history of being a seer of the future within our industry, and I do think you will ultimately be proven correct that hookless will be the future in almost every category of cycling. My issues with it, however, are much more technologically rooted in the present day where I feel that the industry has been a bit intellectually lazy, resulting in both a higher level of risk and confusion for consumers, while at the same time holding us back from developments in hooked and hookless that could bring actual performance benefits.

For starters, and you've mentioned this before, hookless did not start as a performance related technology seeking any actual consumer benefit. This was a manufacturing advance that allowed companies to make carbon wheels both cheaper and more quickly than they can make hook bead style rims, and as a result, almost all of the 'benefits' attached to hookless thus far have been the creations of marketing departments. Not to say that there aren't potential benefits here, slightly lighter and cheaper carbon wheels would be a good thing, there is also a lot of opportunity for improved rim impact strength and bead shapes that minimize tire damage under heavy impact scenarios, but I am yet to see a single feature/benefit pair from anybody's marketing department actually play out in lab or wind tunnel testing, and I'm also not really noticing prices come down either. Having said all of that, I cannot think of a single manufacturing technology which provided cheaper and faster means of production that was left unused in any industry, over the long arc of time, this fact alone tells me hookless will almost certainly prevail.

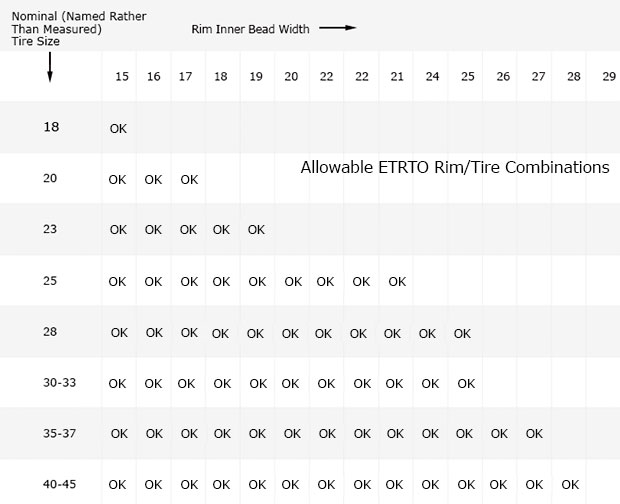

My primary issues with the hookless of today come down to the Industry/ETRTO's decision to combine hooked and hookless into a single compatibility chart where tires are limited to inner bead width and hookless has the added stipulation of 5bar/72.5psi max air pressure. What we've seen in the lab is that with modern tire constructions and tolerances, the combinations for hooked beads are now being dramatically held back in an effort not to create dangerous combinations for hookless rims, while at the same time, some hookless combinations seem to be really close to the edge in terms of safety.

For example, a typical tubeless tire can handle 1.4-1.5x max sidewall pressure (110% of sidewall is the ISO standard) when fitted on a hooked rim with of at least 3mm narrower bead seat width. So combinations such as a 28mm tire on hooked 25mm bead seat, a 32mm tire on hooked 29mm bead seat, and so on are extremely robust in terms of tire blow off while fully optimizing tire handling and rolling resistance. These combinations also tend to create extremely aero tire/rim interfaces and allow for tire/rim combos that observe, or come close to the Rule of 105 (rim measures more than 105% of tire width) which is a good predicter of both low drag and improved stability at higher yaw angles. In a nutshell, these combinations on current hooked rims tend toward excellent handling and aero properties while also demonstrating solid engineering safety factors.

With hookless interfaces, on the other hand, we start to see some pretty big problems when the tire/rim width delta gets below 5mm or so, and the ETRTO chart is quite strange, requiring the rim to be 5-12mm narrower than the tire for most sizes, but only requiring 2-3mm smaller for 25 and 28mm tires. So you are allowed to mount a 25mm tire on a 23mm rim and a 28mm tire on a 25mm rim, but you are also only allowed to mount a 32mm tire on a 25mm rim. While this decision allows for maximum handling and aero properties for those 2 specific tires, it considerably reduces blowoff pressures we've seen 25 and 28mm tires blow off of hookless rims at less than 80psi. This is worrisome as these are the tire sizes people want or need to be riding at higher pressures, and with tires and rims now having their own max pressure indications, not everybody is going to understand that the rim design is now driving max pressure.

We also have to consider that the average floor pump has a +/-5% gauge accuracy when new and all of them experience gauge drift with age, most commonly caused by strain hardening of the bourdon tube inside the gauge leading the gauge to under-report pressure, so when we consider the variables this feels like flying way too close to the sun for my liking. At the same time we are pushing safety limits at the smaller tire sizes, limiting a 32mm tire to a 25mm rim, or a 45mm tire to a 28mm rim holds those tires back from achieving their performance potential in terms of handling and rolling resistance while also outright preventing the design of any rim on which either of those tires could ever demonstrate any aerodynamic performance.

In a sense, the current rules and recommendations around hookless have us pinned in a corner between low engineering safety factors for smaller, higher pressure tires, and stifled innovation and subpar handling for wider, lower pressure tires.

So how does hookless become the future? For starters, we need rethink the ETRTO and develop some science based, data driven strategies that allow both safety and innovation across all tire widths. [Below is the ETRTO's hookless tire/wheel guidance from this past year.]

These size limitations are nonsensical and do not seem to be based on any actual data or calculation from what I can tell, but it makes no sense that a 33mm tire is treated the same as a 28. My theory is that they've skewed all of the rim widths narrower for wider tires as hookless rims (which currently tend to be wider) require that the bead seat be much narrower than hooked rims to avoid tire blow off, and allowed for narrower rim/tire differences in the narrower tires which are assumed more likely to be hooked? I'm only guessing..

Regardless of the intention or thought process behind the current state of this standard, what I do know is that this chart is holding us back significantly from a number of aero, rolling resistance, and handling related design opportunities that could be unlocked if we were to split the hooked and hookless worlds apart in terms of the fitment chart and pressure recommendations.

My vote would be to simply separate these two worlds based initially on tire size, and then drive rim width as a percentage of tire width, and then pressure recommendation based on that combination. From my data, I'd suggest 32-33mm as the crossover number as that is the largest size that people are still using with higher pressures (yes, people at events ask me to put 100psi into 32mm tires every single weekend, so we also need more education). 32mm seems to be the largest size before aero really starts to fall apart, while also being the narrowest size I feel comfortable running hookless based on our internal testing experiences. We could then say that 33mm tires and smaller run hooked beads and max bead width ~85-90% of tire width. Tires 34mm and larger run hookless and max bead width ~70-75%mm of tire width. Similarly, some sort of tire pressure curve should be used to allow the max pressure of the tire to be driven by the inner bead width of the rim on which the tire is fitted.

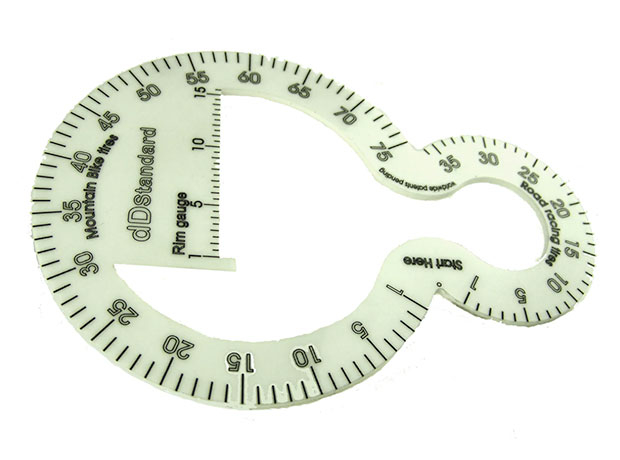

The last challenge to solving this will be changing the way we measure and talk about tire width measurement. Currently different companies calculate tire width based on the tire width when mounted on an arbitrary rim with a bead width of their choosing, so in a sense all of my examples above are wrong as the tires will measure quite differently depending on rim width and tire brand. In this new system we would want to move to something like the dD Standard proposed by Josh Deetz some 15+ years ago. This system gives you a quick calculation of measured tire width for a given rim width and is based on tire circumferential length of the tire casing. Moving to a system like this would allow riders to quickly determine the actual tire width based on their rim, from which they can more accurately calculate optimal (and safe) tire pressure.

Ultimately, splitting the standard and changing the measurement regime would allow both hooked and hookless to play to their respective strengths while dramatically improving clarity for the consumer making the buying decision. So while I'm not at all a fan of the hookless we have today, I can get very excited about the hookless we could have if we attack this problem holistically and with vision. History teaches that changing a standard like this typically takes 10-15 years, so I am reminded of the Japanese proverb that the best time to plant a tree is 20 years ago, the second best time to plant a tree is right now.

Dan writes: I’m with you 100 percent that the ETRTO’s guidance is probably based on guys haggling in a room rather than pure science. The obvious example is max pressure which seems non-random at 72.5psi but is really measured in kilopascals, as in, it’s 500 of them, aka 5 bar. Not 523 kilopascals, or 488, but a pretty handy 500 and that sounds like a compromise of some sort. But…

I have a unique layman’s perspective on this which is that in my Forest Gump manner of standing athwart history through dumb luck I’ve been able to ride many or most of the hookless road wheels and conforming tires. I daresay because of my right place / right time luck I’d like to know who has more experience with these wheel and tire combos. Over 5 years of hands-on mounting and dismounting tires, observing and measuring them, riding them, I just can’t find a downside. In fact, all my favorite road wheels are my hookless wheels and I have some very nice, pricey, well-regarded wheels with hooked beads. One caveat to this: Some of my favorite road hookless wheels are actually allroad hookless repurposed to road (I can get a 30mm tire on a 25mm inner width allroad wheel and it’s a perfect match for my use). Why do I always choose the hookless for my own pleasure riding?

With the stated proviso that these are impressions rather than measured tests, it starts with fitment and I just think it’s easier now for tire brands to make a tire that fits precisely at the bead because the ETRTO has prescribed the radius in the turn from bead shelf to rim wall; the height of the bead lock; the distance from the bead lock to the rim wall; and the G height. The tire is not deformed by the bead hook which means fitment is exact. I tend to get really snug tire fits and certain systems – CADEX tires on CADEX rims for example – are airtight for vulcanized systems. [An example of this CADEX rig is in the pic just above.] While counterintuitive, I get better tubeless air seals with hookless than with hooked.

There is no more concern that the bead will damage the casing – remember the ENVE and Challenge kerfluffle and that’s only the best remembered incompatibility, not the only one – and to warm your heart the tire isn’t pinched and therefore creates a smooth transition from rim to tire. On that aero statement, again, this is an observation, nothing more. But it’s just undeniable that to the eye the wheel/tire transition is much smoother on a hookless system.

So that’s what I like and, for sure, I’m liking it a lot more now than I was 3 or 4 years ago when tire companies didn’t have a set of guidelines to follow (and for this I am indebted to the ETRTO and it appears ISO will mirror the ETRTO from what I’ve heard). But there are certain designs about which I’m less sanguine. I like hookless if the rim wall is not too thick. I’m riding a wheel now that has a very thick rim wall and I guess I feel that some wheel brands are taking liberties with hookless to manufacture wheels using unconventional processes. Because it’s easier now to make a wheel I wonder whether that will open the door to products that are – at least – inelegant.

Then there’s the knowledge requirement for consumers, for example, the delta between nominal tire size and inner bead width which, in my experience, seems to be 5mm as an ideal (versus the 2mm in some cases allowable by the ETRTO). I just would never ride a tire that’s only 2mm wider than the rim width. I find that 5mm still gives me a rule of 105 profile as long as the rim is toroidal (or something like toroidal) – a 30mm tire on a Zipp 353 NSW is just ideal [that rig is pictured just above], and that’s smack on that 5mm delta. And of course you have to remember the pressure. But I guess I don’t find that onerous because if we need to know best tire pressure anyway – hooked or hookless – it’s not a lot different than lube prep or tire prep or any other technical knowledge.

But this is where I part ways with my hookless manufacturing friends: This is a tech that only works with a 28mm tire and larger. I’m sorry, but the idea – and brands are still flogging this – that a 25mm tire can work on a hookless wheel is just not sound. So, I’m a big hookless fan with that asterisk. In fact, several asterisks: 28mm tire and larger; made by wheel and tire brands that know what they’re doing; at the right pressures; with a good pressure gauge beyond that which comes on a compressor or floor pump. [My current faves for performance road riding are the Zipp 353 NSW w/Schwalbe Pro One shown above, and the CADEX 50 Ultra wheels with the new Vittoria Corsa Control Pro pictured just below.]

Josh writes: I wonder how much of your hookless wheels being preferred is potentially due to them being the newest ones? I think we certainly are seeing hooked rims die off quickly making comparisons of wheels of similar vintage ever harder?

You are right that hookless tends to lead to a nice visual transition from rim to tire, but what I've seen in the tunnel is that this rarely translates to faster setups as the rims generally end up being a bit too narrow to recapture air off of the leeward side of the tire once the system sees any yaw. As hookless rims must have narrower bead seats than hooked, the solution here will be thicker beads which will make for less smooth transitions at the rim/tire, but will allow the rim to exist out in a spot where it can recapture flow more effectively. I imagine that the fastest hookless setups will end up being essentially hooked rim shapes where the space under the hook is just filled in. Of course this will negate some of the weight benefit unless the beads become hollow or foam filled.. this also feels like a nice way to improve impact performance but I'll leave that to the manufacturers.

While I laughed at your Forest Gump reference it (and your general humility) does obscure something important about you, which is that you have significant mechanical skill and knowledge compared to the average consumer, you have access to high quality tools and information, and are also a curious and engaged consumer of these products in a way that the majority of consumers are not. This is a great thing, but can also shield you from getting the 'customer experience' as you are potentially doing things you don't even realize which others may or may not be doing. We have a line in our test lab regarding this: "Did it work, or did you make it work?"

Case in point, there is a hookless, tubeless combo that I rather like to ride, but required 2 extra wraps of rim tape to pass blow off testing (and also to seat the tire in the first place). I get it that manufacturing tolerances are hard to hit, but using rim tape to push the rim to the high end of the circumferential tolerance to seat the tire or to improve blow off testing is just a bit too far over the line in my opinion. While hooked beads might not fix the tire seating issue in this case, they would have certainly fixed the blowoff pressure situation.

I know how much you like the CADEX setup and that really is a great example of 'just works' as are a number of the system engineered approaches from ENVE and ZIPP and others. Yet, we have to also remember that one of the things people love about cycling is the ability to experiment and change and 'upgrade' and so on, so while systems engineering has proven to probably be the most effective solution to date for bulletproof, high performance hookless, I don't see this being the ideal long term solution as people want options and like to break the rules by experimenting with new and different combinations.

While I know that hookless really is generally robust in the larger tire sizes as your experience has shown, I will say that in the 100+ tires we've tested over the last few years on 40+ wheels, we've had 6 blowoffs in tire seating, 3 blowoffs below the 110% ISO test, and 1 blowoff of a wheel just leaning against a wall. Every single one of them was on a hookless rim and following ETRTO guidelines. Or stated from the other side, we've never had a hooked tubeless blow off, and that's from a larger sample size and includes combinations that violate ETRTO in the pursuit of performance gains.

Case in point, the setup that has most excited me in the last few years is a 32mm Continental GP5000TR on the 3T Discus 45/40 rim. This is a 32mm tire on 29mm hooked bead with 40mm outer rim width, totally in violation of ETRTO, but exceeds the blowoff pressure of the same tire on an ETRTO approved 25mm hookless bead. In this setup the tire measures 35.5mm wide and produces a near seamless toroidal rim/tire shape which tests lower drag than most any traditional road racing wheel with 25 or 28mm tire while also showing some of the most neutral aero steering torque values of any setup I've ever seen.

It was this setup (and subsequent others we've experimenting with) that really opened my eyes to the whole world of opportunities out there that nobody is exploring because the engineering time and dollars are being spent on making hookless combinations that aren't dangerous rather than focusing on pushing performance boundaries.

I agree with your last paragraph almost entirely.. change 28 to 32 and I think we're in alignment! If we can make hookless with an asterisk one chart, 33mm tires and above, and then set the performance engineering groups loose to push the limits of hooked I think we could both get what we want and would likely see a less confused consumer and happier shop mechanics as well once more systems just work.

[Listen or read to more of what Josh says and writes on Marginal Gains or at Silca.]