ENVE continues to build a solid foundation in triathlon, and already enjoys wide representation in the world of mountain bikes. However, if you talk to their employees, it seems that their heart might just lie in the middle ground between those two worlds, the amorphous segments of gravel and “all road.”

Our publisher, Dan Empfield, has a set of 650b gravel wheels from ENVE, and I took the opportunity to try the SES AR (All Road) 3.4. While my wheels could be used for light gravel, they feel most at home on rough pavement – which are the real-world streets for many Slowtwitch readers. As road and triathlon bikes gain more tire clearance, we’ll start to see more wheels like the AR 3.4 show up as original equipment, with wide rims and tires gaining further market share.

To begin, we’ll do a quick overview of how the ENVE lineup is arranged. If you’re on a tri bike with limited clearance, the standard SES series is likely where you’ll start. These rims are available in multiple depths, for both rim and disc brakes. Their width is considered to be in the average range these days, with internal dimensions in the neighborhood of 18-20mm. Depending on model, you can still get tubular-compatible rims, too.

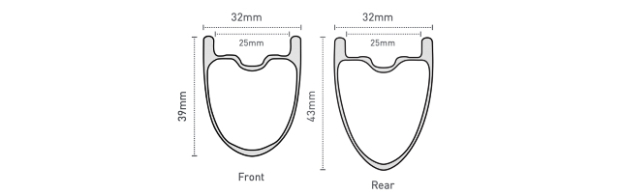

The AR line is the next step up in ruggedness, with two depths available – the AR 3.4 (above) and AR 4.5. Actually, it’s a total of four different rim depths, as ENVE likes to pair shallow front wheels with slightly deeper rear wheels. The AR 4.5 can be had in tubular or clincher, with the newer AR 3.4 available only in clincher. Consider them fit for endurance road bikes or all road bikes, which often have tire clearance of about 30-35mm.

Finally, the G-series wheels are clincher-only gravel wheels, with super wide profiles and an option for 650b diameter.

The AR 3.4 clincher rim profiles can be seen above. They are clearly much wider than traditional road rims. ENVE recommends a minimum of a 28mm tire, but note that the actual inflated size of the tire will be larger than this – we’ll explain why in a moment.

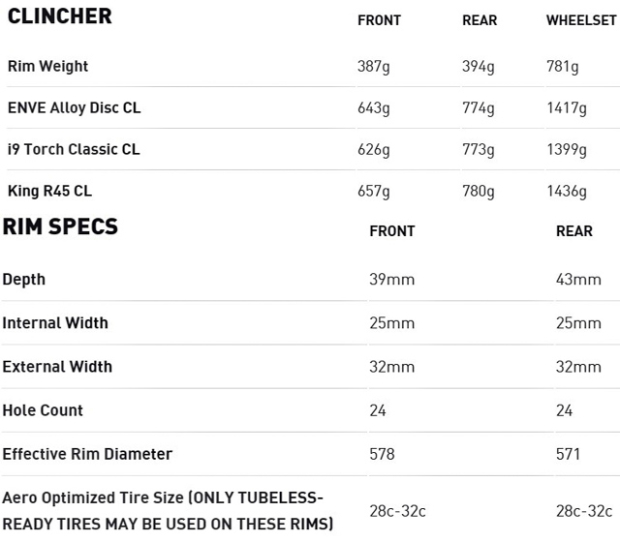

Full rim specs are above, with complete wheel weights varying based on the hub model.

Our test wheels included the alloy ENVE hubs with Centerlock disc compatibility and a SRAM XDR driver body. Wheel lacing is 24 front and rear spokes, with 2-cross lacing all around. While this style of lacing with j-bend spokes may not be the most exciting, my experience has shown it to be the most reliable and easiest to service.

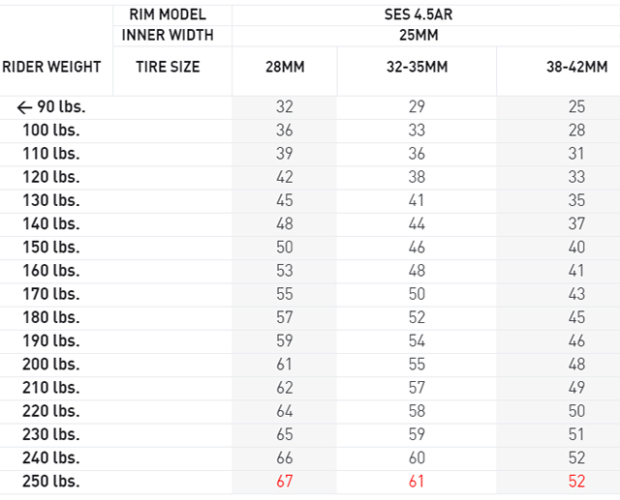

Next, we’ll cover the topic of tire pressure, which is where things get interesting. The above chart shows ENVE’s recommended pressures for the AR series, based on the tire size and rider weight. At first glance, these pressures might appear to be quite low – and they are for old-school road riders.

However, there is a hidden piece of information, and that’s the fact that the actual inflated tire size will be substantially larger than what’s printed on the tire label. Case-in-point, here is a caliper on my 28mm Schwalbe Pro One tubeless tires (note that they’re the 2018/2019 model):

My "28mm" tires inflated to 32.4mm wide at operating pressure. You see, most tires are still labeled based on older and out-of-date ETRTO standards, which assume internal rim widths of about 15mm. Modern road rims are wider than this, and spread the tire casing to increase the actual inflated size. That means that you should treat your tire and its pressure based on the actual size that it is – not what’s printed on the label.

I’m in the neighborhood of 195-200 lbs., so ENVE’s pressure chart recommends 60psi for me. This lines up exactly with what I’d normally run in a tire of this size. Over the course of my testing, I ended up reducing the pressure slightly to about 55psi, which felt like the right point for ride quality and grip.

The final rub is that some of the latest tires from the likes of Schwalbe and Continental are starting to correct for newer wide rims. They’re based on a new assumed standard of a 19mm internal rim width, rather than a 15mm width (in other words, a 28mm tire will run true-to-size on a rim with a 19mm internal width). In effect, the new tires are being downsized, a trend that we expect to continue.

ENVE’s AR series rims are hookless. That is, the inner sides of the rim edges don’t have protruding bead hooks, which were designed as an extra fail-safe to retain tires that might not be manufactured to the right diameter, or have beads that stretch too much. We’ve reported on this before, but the gist is that the hookless design allows for lower manufacturing costs, along with lighter, more durable rim edges. Note, however, that you must use tubeless tires on ENVE’s hookless rims (which have stretch-resistant beads) – and that even some tubeless tire models aren’t allowed. Notable disallowed tires include the Continental GP 5000 TL, Specialized S-Works Turbo 2Bliss Ready, and some models of Hutchinson… Check out ENVE’s website for a full compatibility list.

While brands like HED suggest that bead hooks push the tire inward to constrain its width (for aerodynamic purposes), ENVE representatives say that they’re looking at the larger picture of tire and rim performance. They quoted giving up about one watt of aerodynamic performance by going hookless, but this also gave the AR 3.4 improved stability and a three-watt improvement in rolling efficiency, for a net gain in performance. I don’t have a test lab to validate or deny these claims, but the take home is that there are two different schools of thought.

Real-World Testing

I rode the SES AR 3.4 wheels as part of a the Empire endurance road bike from Fezzari. The wheels came set up in advance from Fezzari with ENVE tubeless rim tape, and about 35ml of Stan’s NoTubes sealant per tire. Tubeless tire/rim fit is always a concern for us, so I removed and reinstalled one tire to see how this combination panned out:

First, I removed the Stan's tire sealant using the KOM Cycling Sealant Injector. Getting the tire off of the bead shelf took some effort, but it was far from impossible. Once that was done, the tire went on and off the wheel very easily. A consequence of easily installed tubeless tires is that inflation often isn’t possible with a floor pump – and my wheel required compressed air to seat the tire. I prefer looser fitting arrangements like this, so I can install a spare tube on the side of the road in the case of a puncture that doesn’t repair via the liquid sealant (it happens).

Out on the road, the AR 3.4’s delivered easy handling, no technical issues, and sufficient stiffness for my weight. The 4.5 rim depth would likely have an aero advantage, but I also find that deeper rims also tend to cause a less forgiving ride. With a sweet spot of 55psi, I felt confident hitting rough patches and bumps, and like I could easily take on dirt roads.

As you know, Slowtwitch is a triathlon-focused site, so does that mean that you should ride these AR 3.4’s on your tri bike? Yes and no. The wheels are fantastic and would certainly perform well for triathlon, were it not for the limited tire clearance of most tri bikes. Several new bikes are moving up to 28mm tire clearance - shy what’s needed for these wheels. I think this will continue to evolve over time, with frame clearance steadily opening up.

As it stands, the AR 3.4's are the type of wheel I’d recommend for just about any road-riding athlete in the middle of the bell curve. You want something versatile, ready to take on fast group rides or dirt roads. You want a rim depth and shape that will look good and perform well, without catching crazy amounts of wind or screaming "racer." The starting price of $2,550 isn’t cheap, but is comparable to most competitors’ products in this range. If they fit your budget and you’re ready to roll with road tubeless, the AR 3.4 ought to be to your list of considerations.

ENVE.com