Shimano GRX is now available in 12-speed mechanical with a few different drivetrain options. Here, I provide my thought process when building a TIME ADHX 45 for gravel racing this season. Later this year, I will provide some in-depth reviews on different aspects of this bike in the context of gravel racing. For now, I make a case for why you should consider mechanical GRX 12-speed, rather than wait for the inevitable Di2 follow-up. I also pick up where Dan left off with his argument for cockpit adjustability and against complete internal routing of hoses and cables.

Purpose

This gravel build is for racing. Plain and simple, I wanted to build a go-fast gravel bike that I could race this season. In the past, I’ve raced gravel on my cyclocross bikes with 35mm gravel tires. I’ve been curious to race gravel on 40+ mm tires, and I have three races planned for April & May:

4/20 Barry Roubaix, Michigan, 62 miles, 4,000 feet of climbing

4/28 Paris to Ancaster, Ontario 43 miles, 1500 feet of climbing

5/4 Black Fork Gravel Grinder, Ohio 54 miles, 5,000 feet of climbing

Of the three, Black Fork is closer to what most may consider in the “spirit of gravel” with ~1,000 feet of climbing for every 10 miles. Barry is one of the oldest “gravel” races in the country (first edition was in 2009) and features more long rollers than steep climbs. P2A is a point-to-point mix of asphalt, bike path, single track, and Amish farm roads (with the occasional mud bog thrown in for fun). I’ve done P2A a couple times before; the course is always a little bit different depending on permissions from property owners. However, this will be my first time racing Barry and Black Fork.

Frameset

My friend, teammate, and long-time bike fitter, Jim Baldesare, told me at a recent fitting session that the current TIME geometry is ideal for my fit. At 6’3” with a short torso, I need a ton of stack. This means my first consideration for any bike is head tube length. I also need a fairly relaxed seat tube angle, so I don’t have to slam my saddle all the way back. The TIME frames are around 73 degrees for seat tube angle, which is ideal for my fit. Before rediscovering TIME, the frames I found to fit these specs are the TREK Boone and Crockett. I own two Boones for cyclocross and have been using my Crockett for daily training and gravel racing. Since rediscovering TIME and their support of our master’s team, I have been racing crits and road races on an ADH01. It’s by far my favorite race bike of all-time. I was worried about it being too nice to race, but it took all the abuse I dished out, including the endless concrete expansion joints of Milwaukee at ToAD.

When the TIME ADHX came out, I wasn’t sold on the frame having a max tire clearance of 38mm. Everyone I was talking to in the gravel racing scene was telling me that I needed to go with bigger tires, so I wanted to give that a shot. Therefore, I was excited when TIME released the ADHX 45 with max tire clearance of 45mm. In a recent podcast, TIME owner Tony Karklins discusses how and why the ADHX was developed and has since been rebranded as Allroad, as well as why TIME answered the call for bigger tires with the ADHX 45. It’s worth a listen; Tony’s story in the industry put together a lot of pieces for me over the last 20+ years. Make no mistake, the TIME bikes are race bikes. You would want a different frame if your needs require carrying lots of gear for adventures, for example.

However, I did hesitate (again) on whether or not the ADHX 45 was too nice to race gravel. These TIME bikes are works of art, and the paintwork is stunning. I decided to go for it, recalling the abuse my ADH01 has taken in crit racing. Although, I did decide to get the frame ceramic coated because rock strikes are inevitable. It was a choice between ceramic coating the whole frame or 3M protection film on the underside of the downtube. I’ve done the 3M tape protection on past frames and wanted to give the ceramic coating a shot. So, we’ll see.

The Case for Mechanical

After years and years of racing on SRAM, I’ve gradually converted my bike stable over to Shimano. SRAM is nice and super easy to install; I regularly do SRAM builds for friends and teammates. Yet, I prefer Shimano, and I prefer mechanical. I’ve had a few Di2 bikes in the recent past, and I was turned off by the hassle of battery charging and the high expense of spares. Admittedly, I’m a bit of a retro grouch when it comes to electronic shifting having been shaped by the mindset that your race bike should be spec’d with readily available and preferably inexpensive parts.

Also, I don’t like to race on anything I can’t fix on the side of the road. For me, electronic shifting adds unnecessary complexity with very little gain compared to mechanical. I’ll concede that it’s much easier to build and maintain a bike with electronic shifting, but I can’t help but to think how I might pay for that convenience when I’m stranded on the side of the road because something I can’t fix went wrong with the electric shifting. On the Di2 side, that fragile wire to the rear derailleur makes me nervous. Maybe less so in the context of gravel, but more so in the context of criterium racing. I’ll also concede that the shifting is crisper with less effort than mechanical, but Shimano mechanical is very, very close if installed properly.

Drivetrain Choice

Shimano GRX 12-speed mechanical is offered with three major drivetrain choices. Shimano has branded these three choices with not-so-helpful labels: 1). UNDROPPABLE, 2.) UNBEATABLE, and 3.) UNSTOPABLE. I’d argue that two of those choices are appropriate for the type of gravel racing I have in mind, and the third choice is more for an adventure set-up.

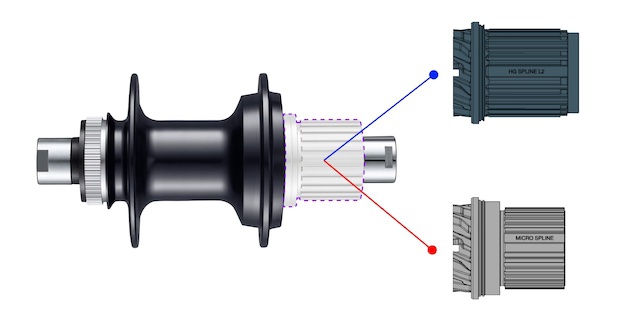

UNSTOPABLE, as in no climb is too steep? What I consider to be the third choice for adventure gravel riding, this option is a 1x12 drivetrain with a 40 or 42 front chainring and a massive 10-51 cassette. That’s close to mountain bike gearing, which may be required if you are hauling camping gear and/or climbing steep gradients for long periods of time. This setup has a specific derailleur to accommodate the 51T max cassette (RD-RX822-SGS). Note that 10T cassettes require the Microspline freehub body.

UNBEATABLE, as in a 1x is all I need to win? I consider this drivetrain option to be geared for one-day riding and racing. This is the same as the UNSTOPABLE option with a 40 or 42 front chainring, but the cassette is 10-45 and the derailleur is different (RD-RX822-GS). Most people can make use of a 1:1 bailout gear or greater in the context of riding and racing on gravel courses that fit the 1:100 ratio (miles:climbing feet). I do love the simplicity of 1x; my Boones and Crockett are setup with 1x Wolftooth/Ultegra RX 11-speed groups. However, I have found when racing gravel that I’m often wanting the “gear between” the cogs of the cassette on a 1x setup. This is usually when I’m alone and slogging it out on a climb.

UNDROPPABLE, as in it is 2x but don’t worry about dropped chains? This is the best option for me, because it gives me the most choices of gear ratios, as I build fitness and attempt to get back into race shape. The crankset comes in a 48/31 and cassette options include 11-34 or 11-36 for use with the RD-RX820 rear derailleur. Note that these cassettes have a small cog of 11 and require the Hyperglide L2 freehub body. I opted for the 11-34 cassette with the reasoning that would provide enough gear beyond a 1:1 to get me through the races I have planned.

If you are piecing this group together yourself, make note of the which freehub body and rear derailleur your cassette of choice calls for. I found this the most confusing part of learning about the new 12-speed GRX. There are three rear derailleurs and two freehub bodies, so there is bound to be some mistakes made when ordering if people aren’t careful.

Cockpit Choices

I’m not a big flare kind of guy. I don’t like crazy wide drops, and I don’t like my hoods angled in. Yes, that’s part retro grouchy, but it’s also what is comfortable to me over the long haul. Of all the gnarly gravel descents I’ve done in the Appalachian foothills and mountains, I’ve never felt a need for really wide drops for stability. This preference is also a product of being accustomed to sliding around and bike driving on a cross bike with 42mm bars that only flare to 44mm in the drops. I didn’t want any more than 10 degrees of flare, so for the Shimano PRO line that meant the LT Gravel Alloy bar. All the other alloy and carbon bar choices from PRO featured even more flare. However, I did bump the bar size out to 44mm at the hoods, which with 10 degrees of flare bumps the drops out to 48mm (center-to-center). That’s seems plenty wide for my riding style.

I also chose the LT Gravel Alloy bar because I had no plans to route the hoses and cables through the bar or the stem. If it’s a new bike, I don’t like to route the hoses and cables in such a way that I cannot easily swap out the bar or the stem. I may hate this bar and want a different one, and I may get fit on this bike by Jim and he will recommend a different stem length. In line with Dan’s reasoning, I see no upside to internally routing hoses and cables.

I did have the option of internal routing available. TIME specs the carbon FSA K-Wing AGX handlebar and the NS ACR Stem for the ADHX 45. This combination is really nice and looks great when everything is hidden, much more so than the Deda options TIME offers. However, I cannot lean into a guess on liking the feel of the handlebar and the appropriateness of the stem length and height for my fit while going through the laborious process of routing hoses through the handlebar, stem, stem spacers, and head tube.

And, let’s face it. Internally routing both hydraulic hoses AND both shifter cables would be a major pain in the butt. Maybe with just the rear cable housing on the 1x groups, but with the 2x it wouldn’t be fun. If I was doing all this internal routing for a customer at a shop, I would be charging extra.

Even with routing the hoses and cables externally, it was still a bit of a chore to size the cable housing at the appropriate length. The hoses are easier because they can be cut after everything else has been installed. I think the result of external routing on the ADHX 45 is tidy and plenty “aero.”

Cable Routing

TIME doesn’t make running mechanical 2x on the ADHX 45 very easy. They combine housing stops with their cable guide underneath the bottom bracket. That seems straightforward, but the housing stops aren’t deep enough to hold the ferrules in place. Therefore, I had to install the derailleurs before the bottom bracket so that I could put tension on the cables and hold the ferrules in place.

On my cyclocross bikes, I’ve adopted the habit of running Jagwire sealed cables. I find that they prolong the life of the shifter cables and the chore of removing the bottom bracket to replace them. In some cases, I have drilled out the stops and run full housing to the derailleurs. The new Boone now features this design. This would have been possible on the ADHX 45 in theory. I could bypass the cable guide below the bottom bracket and run housing to the rear derailleur. The new Shimano front derailleurs include a cable housing stop, so that’s also possible with 2x. However, I did not want to drill out the front derailleur cable hole to accommodate 4 or 5mm cable housing on a brand new TIME frame. So, I went by the book and routed the sealed cable system through the cable guide under the bottom bracket.

The Rest of the Build

Everything else went together without a hitch.

The 40mm Challenge Getaway tires are a nice match to the carbon RX880 wheels with hooked rims that have a 25mm internal width. I’m not convinced hookless is a good roadside repair option for 40mm tires at 30-40 psi. I did use an air compressor to seat the tires initially. But, they appear that they will seat themselves even with a tube and a hand pump (and maybe a squirt of water for encouragement) on the side of the road. I will test that out before race day.

The Stealth saddle with carbon rails is an open question. I tend to find a saddle that works for me and put it on all of my bikes. For going on 10 years, that has primarily meant Fizik Ariones on my road bikes and Selle Italia X1s on my cyclocross and gravel bikes. I’ll give the Stealth a shot in training, but the carbon rails make me nervous as a heavier rider.

The new 12-speed GRX groups feature some changes to the hydraulic brake calipers that are worth noting. The bleed nipple and screw are separate and recessed. They both have dust covers and are nicely tucked away. The previous bleed nipple/screw on GRX 11-speed and other Shimano groups was kind of vulnerable and had a dust cover that was easy to lose. This new design is much better and cleaner. The new calipers also feature 10% more width between the pads and the rotor. I didn’t notice this much, but I will say caliper alignment was indeed “first try” (not in the way LEGO Batman says it).

Another thing that I noticed that I think is new is the hydraulic hoses sealed at the nipple and full of mineral oil. Also the olive is already installed inside the flange flare nut on the shifter. I guess the intent here is to perforate the hose and install immediately in the shifter lever, maybe without the need to bleed? I had to shorten the hoses and press in new connecter inserts, so I went ahead and bled both brakes anyway. Two items that make this process easy are the Park Tool Bleed Kit for Mineral Oil and the Shimano Disc Brake Hose Cut & Set Tool. Life is definitely easier since I added these to my bike shop at home.

More Soon

I’ll follow up with a performance review of this bike. In particular, I’ll be focusing on the GRX 12-speed 2x mechanical group and the Challenge Getaway Tires. I’ll let you know how the bike performed in those three races. I think I’m really going to like the handmade suppleness of the Challenge Getaway Tires on the mixed terrain of P2A, but we’ll see how they fare on the “purer” gravel courses at Barry and Black Fork.

Build Specs

Frameset: TIME ADHX 45 XL Gloss Siva

Bar: PRO LT Gravel Alloy 44mm

Bar Tape: PRO Gravel Comfort

Stem: PRO Discover 110mm

Seatpost: PRO Discover Carbon

Saddle: PRO Stealth Carbon

Shifter Levers: ST-RX820-R/L

Cables/Housing: Jagwire Elite Sealed

Disc Brake Calipers: BR-RX820

Brake Rotors: RT-CL800 160mm

Front Derailleur: FD-RX820

Crankset: FC-RX820-2 48/31 175mm

Bottom Bracket: Kogel Ceramic 386EVO-24

Rear Derailleur: RD-RX820

Cassette: CS-R8101-12 11-34

Chain: CN-M8100

Wheelset: WH-RX880

Tires: Challenge Getaway 40mm

Sealant: Challenge

Pedals: XTR PD-M9100

Weight: 19 lbs. 15 oz.