I have a few new things to say about hookless and yes, anything on hookless is clickbait at the present moment. If my words are helpful it’s because there are so many words flying about this week contrary to what I’ll write below.

Five days ago the UCI “decided to study the [hookless wheel] situation as a matter of urgency with a view to taking a rapid decision,” a move supported by the CPA (pro riders’ union). This is largely the result of pro cyclist Thomas De Gendt’s wheel and if you know exactly why his tire came off his rim please tell me because I don’t. (Not that I haven’t tried to know.) I’m just glad that the UCI and the CPA are in sync and on the job because the last time we had a crisis like this the UCI banned the use of disc brakes in pro tour cycling – with the CPA’s approval – because of the many incidences of disc brakes causing serious injuries. That’s why… err… no pro cyclists ride disc brakes today. [/snark]

Over the last 4 years road hookless wheels have been sold by the tens of thousands and I must ask: Where are the social media posts about the blow-offs? Like we saw with Shimano crank delaminations? Certainly if hookless rims were a hazard we’d see these. But we don’t and if there is data-driven evidence of hookless blow-offs exceeding those on hooked rims I’d sure like it presented. (Crickets so far on that.)

Today, the presumption now with any blow-off – even those like Arnoud De Lie’s finish sprint blow-off last autumn which occurred on a hooked rim – is that hookless must be the culprit. I’m writing to tell you of my experience as a journalist and rider. I’ve tested liberally on the road and in my workshop 8 or 10 sets of road hookless wheels along with all the hooked wheelsets that have rolled across the transom during that time. Over the past year I’ve pretty constantly chosen 1 of 4 wheelsets (when not obligated to test something else): a facsimile of De Gendt’s by-now infamous Zipp 353 NSW (25mm internal bead width); a Zipp 404 (23mm); a CADEX 50 Ultra (22.4mm); and a CADEX Allroad (25mm). Of all the wheels I’ve ridden over the past 3 years these are my 4 favorite road wheelsets (acknowledging I ride the CADEX Allroad, pictured just below, not for its intended use case) and that’s why they’re on the 2 road bikes I own. Those with the 25mm internal widths have either 30mm or 32mm tires (nominal sizes) and they’re my go-anywhere wheels. The others have 28mm tires and they’re my performance wheels (I don’t have a performance body, but I do have the wheels!). Why, out of all the wheels, hooked and hookless, have I settled on these, especially as Gen-1 hookless wheels are my faves over Gen-25 or -50 hooked? (I still ride hooked for my bikepacking and my gravel bike as those wheels solve particular needs.) Which leads us to the next urban myth: That hookless offers no benefit to the user, only to the manufacturer.

Fitment. That’s the primary benefit of hookless to me as a rider. You won’t find hookless wheel brands making this claim and I don’t know why. But in the case of CADEX you lose air in its tubeless system at a rate about equal to a butyl tube in a clincher (depending on the tire). Which is to say, almost zero. There is something about not having that pinch at the bead (I can’t come up with any better explanation) that frees a well-designed tire to sit on the bottom of that rim shelf and against the rim wall flush and tight. Assuming they’re vulcanized or, like the new “Pro” series of cotton Vittorias hold air like vulcanized, I can ride tires in all these wheels for days and even into the next week without having to reinflate (and yes, all are tubeless). I do have a set of carbon tubeless road wheels I can’t ride anymore because the carbon bead has a nick in it, so it won’t hold air. Not likely to happen with a hookless wheelset, because there is no bead to nick. Conceptually it becomes easier for a manufacturer to concentrate on the strength of the rim wall and this motif opens up new manufacturing processes for wheels, as you see with Forge & Bond wheels.

Yes, this makes a wheel easier to manufacture. Just like electronic shifting (once you’re at scale). This is why an electronic road bike is now obtainable for $3,500 of today’s dollars rather than 6000 of your 2014 dollars. (And it’s why a pair of Zipp 303 S is available for not much over $1000 a pair.)

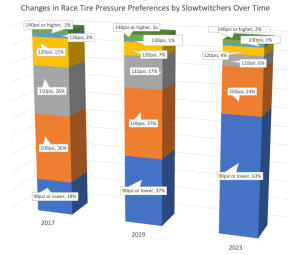

Let me finish with the downsides of these wheels, and other “pro tips” on usage. Pressure calculators (like the very good and oft-used Silca) must be fudged for the wheels I ride. I found that in order to normalize hookless I needed to reduce the pressure recommended for a hooked rim by at least 3psi. Also, as you see in my favorite wheels I’m a fan of wider inner bead widths. Here again, the wider the rim’s bead the lower the pressure. The difference in pressure between a hooked tubeless wheel with an inner width of 20mm and a hookless at 23mm might be 5psi or 8psi. Accordingly I (170lb) ride a 28mm tire at no more than 60psi (unless you can find me a glassy road in California); and I ride a 32mm tire on a 25mm internal width at 48psi. Why the lower pressure with hookless? I don’t know, but my instinct tells me it’s because the tire stands up better in the rim as it is not pinched at the waist, and the verticality of that sidewall adds structure. Note to my esteemed friend (and my favorite things-that-roll expert) Josh Poertner: consider adding fields for inner bead width and hooked v hookless to the online calculator. There is a consequence to this, which is that hookless becomes a viable wheel for those seeking ultimate performance without exceeding the ETRTO’s 5 bar suggested limit. I can’t imagine a case where I would ever ride a tire that would approach that pressure.

My testing but – in all honesty more so my instinct – told me in 2020 when I started riding hookless road that anything smaller than a 28mm tire was not a great idea for this tech. I also found that a 5mm delta between nominal tire size and inner bead width was a good rule of thumb and I stick to that. As to whether it’s safe to ride a 28mm tire on a hookless rim with a 25mm internal bead width I don’t know. Just, rather than arguing back and forth I’d welcome seeing Zipp’s and ENVE’s blow-off testing, and I’d equally welcome knowing any standards agency’s (ETRTO or ISO) data-based rationale for why that combo isn’t safe and appropriate (if that’s how they feel).

Yes, there is some extra rigor required of you if you ride a hookless wheelset. You must make sure the tire is hookless compliant, both in the model (hookless-compliant tires are built with a less flexible bead) and keeping to a tire-to-rim width that is industry agreed (if there is no agreement, perhaps err on the conservative side until there is). You must avoid a pressure greater than 5 bar (72psi) and perhaps someday this guidance will be normalized for rim and tire size (5 bar is low for a 25mm tire but way too high for a 40mm tire, and standards agencies should include blow-off thresholds of 150% of whatever the max pressures for these tires). If you think this is too much hassle I’ve also had, for the past decade, to make sure my tires and wheels were tubeless compliant. I’ve had to make sure my hydraulic lines are bled and my batteries are charged in my shifters, derailleurs, radar, head unit, power meter. This is the life of the modern cyclist.

Hookless is not as game-changing as hydraulic, electronic or tubeless. And it’s not for everyone. My wife is on hooked rims because she is not as rigorous with the pressure gauge as am I. This is the big limiter in hookless at present and why I absolutely do not endorse hookless for the huge swath of cyclists who won’t use a good pressure gauge upon inflation. Nevertheless, out of all the wheels I’ve owned and ridden I find myself now most often on this tech, through no financial incentive (I’m in the long goodbye phase of my bike industry career). I’m certainly not advocating for hookless. I’m advocating against ignorance. I’m sure there are folks who’ve ridden more hookless wheelsets more miles than I have but I don’t know who those people are. What I pretty much do know is that virtually everyone who writes disparagingly about hookless has no experience with this tech. Just as it was with road disc brake.