Today begins my revolt against the unadjustable front end. By “unadjustable” I mean road and gravel handlebars that you can’t move up and down, back and forth, to make the bike comfortable, ergonomic and pleasurable to ride. Today I commence my strenuous assault and I’m going to be a one-person apologist for utility in our industry until I’m 10,000 persons and we don’t continue these terrible industry trends. (This whack-a-mole adjustability crusade of mine is ironic, since tri bikes have gotten extremely adjustable over the past decade while road and gravel bikes have gone the other direction.)

If you’re a bike brand and you make an adjustable front end, but it is so hard to adjust that the user just gives up and rides it as is, you’re not off the hook. If you make a bike that guarantees that every hour of every ride is frustratingly uncomfortable for your customer, you’re not off the hook. If you’re a consumer and riding your bike is like lying in bed in the morning knowing you need to relieve your bladder but the discomfort is not quite bad enough to actually get out of bed, it shouldn’t be like this. A bike that is vaguely uncomfortable all the time is not right and it doesn’t need to be that way.

I asked head of bike design and engineering for a major bike brand and he said, “It’s a bad way to make a bike,” when I asked him about road and gravel bikes with hydraulic lines running through the stem. “But it’s what the project manager demanded.” The product manager, according to this engineer, said that customers demanded that the hydraulic lines be buried inside the bike’s front end, even if it makes the bike virtually unadjustable.

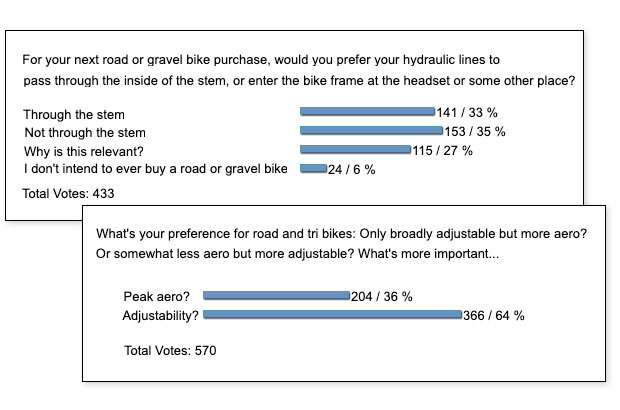

Well… not so much. Not if Slowtwitchers are the customers. Above is how you all answered a couple of polls we took over the last few weeks. Yes, for sure (as you can see) a significant number of folks are willing to give up adjustability. But more are willing to give up a little bit of aero (or just the perception of aero) in order to hit the fit coordinates they need.

Specialized appears to have discovered this over the past decade and abandoned the practice of running hydraulic lines through the now-abandoned Venge. Several years back that company ditched the buried-hydraulics motif for a streamlined but still external hose routing, passing the hydraulic line underneath the stem on its Tarmac SL7 an SL8. (You can see this in the 2 images just above and below.) This allowed Specialized’s flagship road bike, the Tarmac, to remain old-school adjustable (when outfitted with a stem separate from the handlebar) while retaining a clean look that – for all we know – is practically identical in drag to cockpits that run lines through the stem.

Specialized thumbed its nose at perceived peak aero even further with the more recently introduced Aethos, which has been styled a “climbing bike” because of its extreme light weight but really was built as the ultimate ride quality bike. “Light weight was a by-product,” is how Cameron Piper explained the bike to me. The Aethos was borne out of, ‘What could you do if you got rid of everything that kept you from a bike that optimized the ride experience?’ Without meeting a regulation of the ITU, or the constraints of a pro tour rider?” Cameron was the product manager at Specialized in charge of the Aethos, as well as the Tarmac, the Shiv TT, Allez and Allez Sprint.

I contacted Piper about the Aethos to find out whether that bike was a commercial success. “That was not an easy conversation,” he told me when describing the meetings inside Specialized about running the Aethos’ hydraulic lines particularly traditionally. Naysayers were concerned the bike’s “unclean” look would turn off customers. Were Slowtwitch readers outliers who appreciated fit more than the typical customer at retail? Were we the only audience who would accept hydraulic lines flying commando in the wind?

I asked Mark Vautour, a principal at Landry’s Bicycles, an 8-store chain in metro Boston and one of the larger independent customers of Specialized. “Is the Aethos a success or a failure as a commercial product? I wonder how that has worked out at retail.” “It has totally worked out,” Vautour replied. “Most people couldn't care less about aero anything. It is lighter, simpler, and more comfortable and corners like a race bike. You should buy one.”

I asked Woody Smith about the Aethos. He’s the owner of Richardson Bike Mart in Dallas, another mega Specialized dealer. “I just spoke with our GM Pete Kelly yesterday about his new Aethos,” Smith replied. “It is a pound lighter than his old Giant. He mentioned that it is indeed a ‘climbing’ bike. He could feel the difference on the hills and could easily keep up with the group without much effort. We sold a lot of Aethos.”

But Smith also noted that the Aethos arrived during a time when the Tarmac was hard to come by. Craig Abraham, owner of Bicycle Haus in metro-Phoenix, answered similarly. “The Aethos has been very successful for us. We had customers that still had a Venge and a [Tarmac] SL7 alongside the Aethos and when those 3 bikes were still in play the Tarmac was somewhat of the odd man out ride-wise. It was partially a timing thing that was beneficial for the Aethos.”

I asked Abraham whether part of the value to consumers of the Aethos was the ability to change the stem easily, so to make the bike fit more precisely. “We have had multiple customers who switched from other bikes and it doesn’t benefit anyone in the end to bend a customer to the bike. The Aethos was already on the radar for those customers, but the Aethos won out. The Pinarello cockpit and the Scott were out of the question due to internally routed proprietary stems that are only offered in one angle. Manufacturers are heading into a dead end when they make a bike with a handlebar and stem that can’t be changed. It can be very hard to make those bikes fit. One of my personal favorite endurance category bikes is the BMC Road Machine but some folks can’t experience it because of proprietary front end that you can’t change out.”

I have not yet found a Specialized store that has not waxed enthusiastic about the Aethos, when asked about the bike itself or about the bike as a commercial venture. I noticed another recurring theme as I talked to people inside the industry about the Aethos, like ex pro cyclists and bike shop principals. The Aethos is the bike they bought when it came time to fork over their own money for their personal bikes.

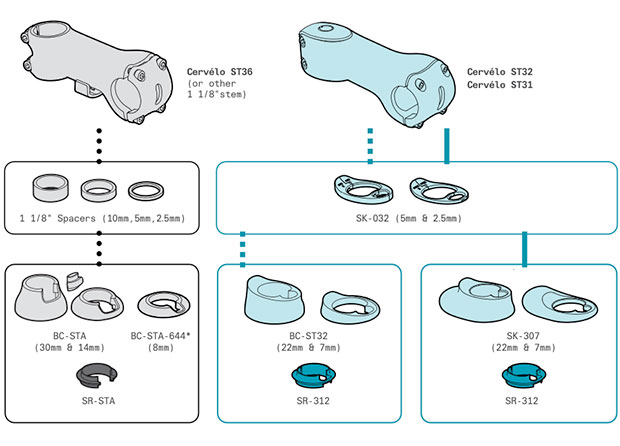

Cervelo is another company that has embraced running the hydraulic lines under the stem. Not throughout the line, mind you. Cervelo offers 3 front end motifs for road and gravel. Easily recognizable is the V stem (above) and I give this bar – with buried hydraulics – relief from my Jeremiad because it is easily adjustable across 2 planes: height and length. The absolute least helpful spec move is the one piece stem/bar that is not adjustable and that does not come in various lengths. I reviewed Colnago’s C68 Gravel a couple of weeks ago and this bar/stem works because it’s offered in 80mm thru 120mm lengths in 10mm increments. But woe unto you if you don’t get it right the first time, or if any change in your fit coordinates may be in your future.

The spec I just don’t understand is the changeable stem that can’t be changed, which is what you get when you run a hydraulic line through a traditional stem. Cervelo does offer this. But they also offer a third option which, like Specialized, is the stem with hydraulics passing under the stem. These two stem options are shown in the schematic above. (Obviously I prefer the ST36 at left.) I’ve used both these Cervelo stem motifs and, in my opinion, you should reconsider buying a bike with hydraulic lines passing through the stem, regardless of which brand makes this kind of bike. Yes, one of my everyday road bike features this motif. I own and ride and love my Quintana Roo SR6, but I had to change the stem twice before I got exactly the stem I need, and that meant pulling hydraulic lines out of the frame – twice – replacing those lines and rebleeding – twice – before I got it the way I wanted it. I have a bleed kit. I know now to bleed hydraulics. I had extra hydraulic hose, needles, olives. Do most customers?

I talked to Graham Shrive, head of design for Factor Bikes and who formerly had that job at Cervelo. “You neatly summarize the root cause of about half the bankruptcies, weird decisions, and confounding designs haunting the industry at the present,” when I asked him about product manages that run design decisions. “Factor doesn’t have product managers. One team designs and specs the bikes.” Nevertheless, Factor also hides the hydraulics inside the bike. “Unfortunately as you noted it makes changing stem length quite a handful, but with the nature of our customer base this is 99 percent of the time taken care of in a fitting exercise prior to the build, as we offer almost 40 combinations of bar and stem width and length, and allow the rider to pick any size prior to shipping.”

I have a problem with this thinking. As with Colnago’s bar/stem the assumption is that your position is perfect and not subject to change. I just don’t find that realistic. It also assumes that if you go to a fitter to establish coordinates that this fitter knows what he or she is doing. Just peruse our Fit Assistance threads on our Reader Forum. That forum is a chronicle and testament to bike fit sessions gone wrong.

As we see with Specialized, and with our own reader polling the perceived requirement (by bicycle brands) that the hydraulic lines be hidden inside the handlebar and stem are just that. Perception. These are design decisions made by product managers based on… what data? Not only can I find zero evidence that hiding the hydraulics inside the stem is customer-driven, If you make cycling sufficiently painful what do you think will be the outcome?

There are 5 cockpit motifs used in road and gravel today:

1. Integrated stem/bar systems. Most of them are terrible.

2. Hydraulics passing through changeable stems. Remains a terrible way to do it.

3. Widely adjustable integrated bar/stem systems. Cannondale’s Knot system. Cervelo’s V stem. Pricey, can’t replace with anything aftermarket, but an elegant, functional solution.

4. Hydraulics that pass underneath the stem and into a hole in the headset dust cover. Perfectly good way to do it. It's the way my other road bike, Cervelo’s R5, does it and you can see the routing in the pics just above.

5. Old school. Like the Specialized Aethos. Perfectly good way to go and in my reporting the choice of many who know bikes and who can afford a high-end (but non-halo) road bike.

“Specialized didn’t always exist in the way it does right now,” said Piper to me. “With the Venge Vias they did pursue the route of going through the stem. That bike had a more complex front end. A lot was learned from that exercise. A lot of lessons that led to where it is today.”

The rest of the bike industry needs to learn those lessons.