DT Swiss makes a range of carbon wheels for both road and mountain bikes. While we have historically focused on their triathlon-and-aero-ready ARC series wheels, today’s article will cover their all-rounder ERC line.

Many high-end wheel companies now offer a product continuum for drop bar bikes, with an aerodynamic choice at one end, an all-rounder in the middle, and a gravel option at the other end of the spectrum. DT Swiss does this with their ARC, ERC, and GR lines, while ENVE’s system includes SES, AR, and G Series. The aero-focused choices typically have narrower and deeper rim profiles, fewer spokes, and a focus on light weight over maximum durability. The gravel-focused wheels have shallower and wider rims, more spokes, and beefier overall construction. The all-rounded wheels like the ERC shoot for a ‘best-of-all-worlds’ design, and are typically marketed for road bike use on pavement and smooth dirt.

DT offers the ERC line in two levels: 1100 and 1400. The 1100 level ($3,240/pair) represents the highest-end product, with light spokes and ceramic bearings in top-end 180 model hubs, while the 1400 level ($2,655/pair) opts for heavier spokes and steel bearings in 240 model hubs.

The ERC line includes 35mm and 45mm rim depth options at both price points. Both feature a 22mm internal rim width, up 3mm from the previous generation wheels. The 35mm rim can be had in 700c and 650b diameter, while the 45mm rim comes in 700c only. Complete wheel weights come in at 1,391g (ERC 1100 DICUT 35), 1,442g (ERC 1100 DICUT 45), 1,468g (ERC 1400 DICUT 35), and 1,519g (ERC 1400 DICUT 45).

Both rim models are fully tubeless compatible and feature bead hooks. DT Swiss appears committed to bead hooks, offering the following reasoning:

Thus far, the market remains mixed, with few manufacturers fully committing to hookless – at least for now.

DT Swiss prefers internal spoke nipples; a somewhat controversial choice. Internal nipples improve rim strength (because they require smaller spoke holes to be drilled), along with a small potential aerodynamic gain. The downside is that they make spoke replacement and adjustment more difficult and time intensive.

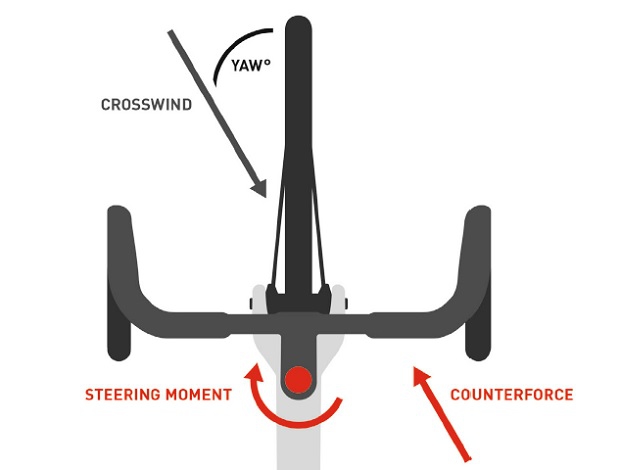

Wheel stability remains a huge topic for most wheel manufacturers. In short, they seek to design wheels that create minimal steering input (though, in my experience, this has less impact on handling than side force - which is mostly a function of rim depth).

DT offers the competitive analysis above, along with this explanation of their ERC wheels’ stability:

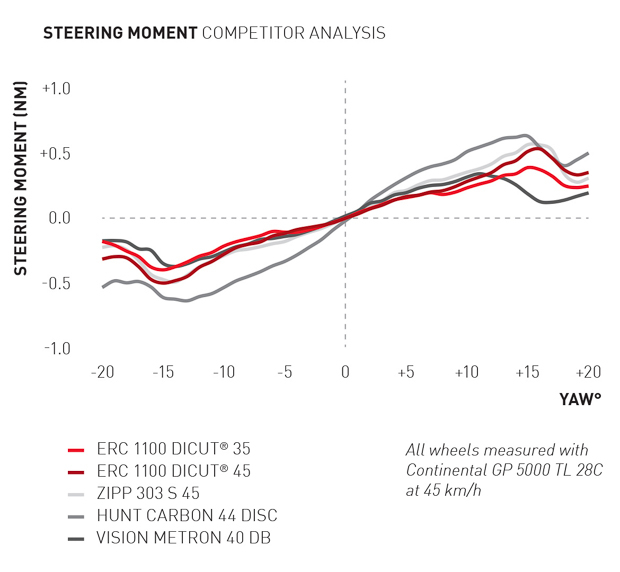

”The chart displays the steering moment of different wheels in Nm at yaw angles between -20 and +20 degrees. The closer the curve to the x-axis at any given yaw angle, the lower the steering moment, which results in a favorable wheelset.

As displayed in the chart, most wheels tested including the ERC 1100 DICUT in 35 mm and 45 mm rim height have a low and evenly changing steering moment.

Based on their respective weighted steering moments, the ERC 1100 DICUT 35 and the ERC 1100 DICUT 45 both feature a generally low and linear progression of the steering moment curve, as well as a smooth stall. All three characteristics combined benefit the rider with good handling and predictable steering behavior of the wheel under crosswind conditions.”

What about aerodynamic drag? DT offered the graph above, along with this analysis:

“The ERC 1100 DICUT 35, despite having the lowest rim height among the tested wheels of 35 mm, demonstrates the second lowest drag value across relevant yaw angles in weighted drag of 13.1 W and an improved drag performance of around 1 watt when compared to the next best competing product.

The ERC 1100 DICUT 45, with 12.2 W in weighted drag, distinctively displays the lowest base drag (drag at 0º yaw angle) of all tested wheels. Within the range of relevant yaw angles the drag performance of the wheel is better by around 2 watts when compared to the next best competing product. A late detachment of the airflow from the rim at a yaw angle of about 15º further shows its excellent aerodynamic behavior.“

DT opts for T-head spokes to reduce spoke twist and frontal profile, along with new 36t Ratchet EXP internals.

These are disc-brake-only wheels. Note that the 180-level hubs even remove sections of Center Lock splines to save a few grams.

DT includes tubeless valves and factory-installed tubeless rim tape. There are no restrictions listed on tire brand, model, or type (i.e. you can use any clincher tire you’d like, so long as it’s at least 25mm wide). DT recommends 28mm tires as the best all-around choice for performance and comfort.

We haven’t had a chance to ride the new ERC wheels yet, so we can’t share our hands-on impressions. I’ve had great experiences in general with DT Swiss wheels over the past 20 years, so it’s hard to expect anything less from these new offerings. The only downside big downside is price, making it hard to recommend the 1100 series wheels (at $3,200+ per pair) unless cost is no object for you. If I had the scratch, I’d likely opt for the 1400 model with 45mm rims and ~32mm tires for my local dirt roads.