Based in Brussels, Belgium, the European Tyre and Rim Technical Organization (ETRTO) oversees standardization for many types of pneumatic tires and wheels, including those used for bicycles. In order to ensure safety and compatibility across different brands, manufacturers must create products that fit within the allowable ETRTO tolerance ranges. If a tire was manufactured to be too large and mounted to a wheel that was manufactured to be too small, it’s easy to imagine the resulting catastrophe (i.e. the tire comes off the wheel, and bad things follow).

We have covered various aspects of ETRTO standards over the years, including the complications that have arisen from the advent of tubeless technology and hookless rims. We also took a tour through the ENVE test lab and detailed their efforts at creating and updating safety standards for tubeless wheels and tires. In fact, it was the folks at ENVE that tipped us off to the fact that ETRTO has taken action to update and clarify their standards for 2020, as they relate to tubeless, hookless, and other modern technologies.

As someone that has had his finger on the pulse of the bicycle wheel and tire business for over 15 years, I can confidently tell you that this is a big deal. People whine and complain about the lack of standardization in the bicycle industry (myself included), but some also lament the slow-moving nature of organizations such as ETRTO. My opinion is that – on the whole – bicycle innovation moves plenty fast, and both the average consumer and the entire wholesale and retail marketplace would benefit from moderating the pace of new products and standards. The focus ought to be on making products that work safely, work every time, and work in concert with products from other brands (in other words, making products that function reliably in the messy reality of the real world). As of today, ETRTO is the big game in town for wheel and tire standards, and I am glad to see these updates.

To sum up my feelings: I prefer a slow-moving standard to no standard, and I think you should, too.

The biggest news is that the long-time ‘ATB’ standard (All Terrain Bike, or mountain bike) for tubeless has been updated to include road and gravel sizes. As many of you know, tubeless started with mountain bikes, and went through about a decade of evolution and fuss before settling in to what we have today – which is largely a situation of confidence that any major wheel will work with any major tire, without a significant hassle or mess in your garage. We’re not there yet with road, but my hope is that clarification of standards will be another step in the right direction.

More specifically, our friends at ENVE called out a handful of things about which they were happy to see.

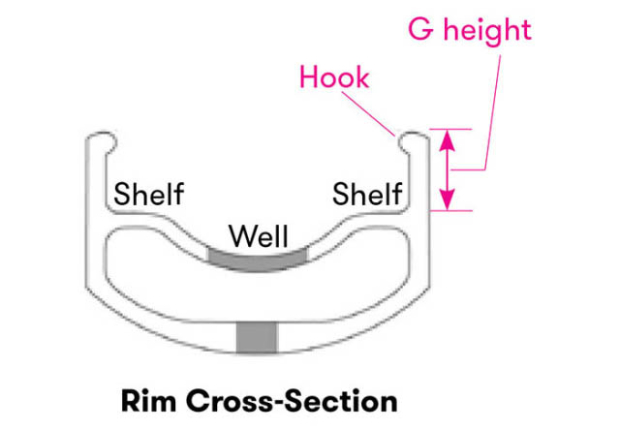

1. Elimination of ambiguity for the BSD (bead seat diameter) for road. BSD is a major key to making tubeless wheels work well. It is the diameter of inner rim; the ‘shelf’ on which the tire beads sit while the tire is fully inflated. Another way to think of this is the inner corners of the rim, right where the tire bed meets the rim sidewall(s).

The BSD dimension has now been clarified as 621.95 +- 0.5mm for all 700c tubeless rims. A tubeless wheel and tire system requires a much more precise fit between wheel and tire, in order to be safe and air-tight without an inner tube. This is doubly important for rims without bead hooks, which act as an additional failsafe in the case of a tire that was manufactured with a too-large diameter, or with a bead that isn’t sufficiently stiff.

2. Air-tight hookless rims (also called Straight Side rims) are no longer specified as being for ATB tires. Rather, this has been broadened to include all tubeless tires.

3. The ETRTO tables of tire and rim compatibility have been expanded to include wider rim designs. This is perhaps the most overdue aspect of the ETRTO standards, and I’m glad to see this update.

Note that this does not mean that ETRTO has budged on the allowable tire sizes on a given rim size. For example, a 17c rim (with 17mm internal width) keeps the official minimum tire size of 25mm… when we all know that untold thousands of people have used 23mm tires on such rims. The rub is that some tire manufacturers are now effectively downsizing their tires to measure accurately on the latest wide rims. For example, a 28mm tire used to measure 28mm on a 13c or 15c rim. The latest products from Schwalbe and Continental measures true on a wider 19c rim. I suspect that we’ll be dealing with this evolution and updating of standards for many years to come.

What Does It All Mean?!

How does this affect you, loyal Slowtwitchers? In reality, there will be no effect to your day-to-day life, at least in the near future. Standards such as these take time to trickle out into the marketplace in the physical form of actual products (keeping in mind that old inventory at retailers and wholesalers must sell through first).

Over time, these updates should serve to improve rim diameter control, leading to more precise tubeless tire fit. There is, however, a remaining large gap on the tire manufacturing side with control of bead stiffness and diameter, which is why ENVE took it upon themselves to create their own test rig and list of officially approved tires for their wheels.

If you’d like to join in the discussion on road tubeless, head over to the Tubeless Super Thread in our reader forum.