It has been a long time coming, but ENVE Composites finally announced a line of lower-priced wheels. For years, we wondered. Would they be aluminum? Asian-made carbon? Or maybe they’d reinvent all of their top-end rims and cut the price of their old products?

The answer? None of the above. ENVE opted to create an all-new line of carbon wheels with their own unique characteristics, and makes them alongside the high-end stuff in their Utah factory. They’re called the Foundation Series, and include two rim depths for road – 45mm and 65mm. There is also a mountain bike offering in the mix (dubbed the AM30), but we will save this article exclusively for the skinny tire stuff.

Let’s start with the basics. ENVE says that the rim shapes are based on the Smart Enve Systems (SES) technology used in their top-end offerings. However, rather than staggering the rim depths front-and-rear, the Foundation wheels use identical rims within each pair of wheels. First and foremost, this is a cost-saving measure, reducing the number of prototypes required for development, and reducing the number of rim molds they must produce and inventory. The layup for each rim has also been simplified, using fewer complex pieces of carbon – and a slight weight penalty for each finished rim. The rims use removable bladders and molded-in spoke holes, just like ENVE’s premium product.

Cost has also been reduced by way of fewer options. These wheels are tubeless-only and disc-brake-only. No tubulars or rim brakes to be found. Also note that they are only sold as complete sets. You might want to run a 45mm front rim and 65mm rear rim, but you can only buy a complete set of 45s or 65s… at least for now. Axles come stock as 12mm front and rear, though they have end caps available for quick release skewers. Freehub options include Shimano, SRAM XDR, and Campagnolo.

The new Foundation Road Hubs are ENVE’s own, and based on their existing alloy hub design. Cost savings come in a couple ways. First, the hub shells aren’t as heavily machined, and feature j-bend flanges. The bearings are NTN steel bearings, rather than stainless steel (which has effectively no impact on bearing life, in my experience).

In essence, you have something amounting to every bit of what an ENVE wheel should be – just detuned a hair - and designed to be produced, boxed, and shipped very quickly.

Performance Claims

Creating a price-conscious product can be a tricky business. You want it to be better than your competitors, but not so close to your top-end stuff that it cannibalizes sales. ENVE appears to have gone to great lengths to thread that needle appropriately.

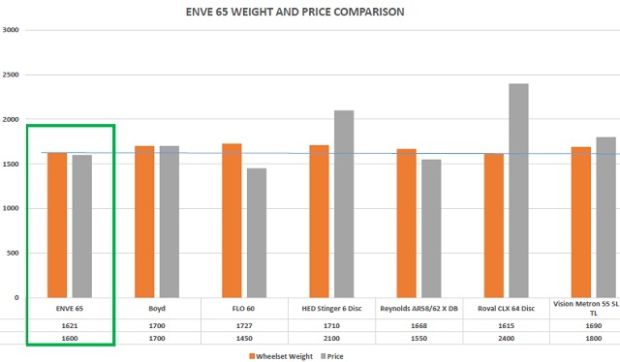

The chart above shows a weight/price comparison between the ENVE 65 (1,621 grams, $1,600) and products from Boyd, FLO, HED, Reynolds, Roval, and Vision. While much of the Slowtwitch audience isn’t particularly concerned with weight, it remains a concern for some. In today’s economy (and in this author’s opinion), it’s the money that does the real talking. The only nit-picking I’ll do is that the HED Stinger isn’t the best comparison, as it’s a tubular-only product. The cheaper Jet series might be a more appropriate comparison, though it uses an alloy rim extrusion. In any case, it’s clear that ENVE is very competitive in both weight and price.

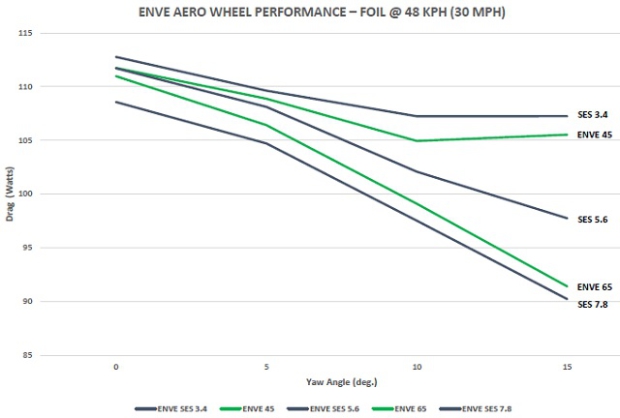

Slowtwitchers care about aero, and the chart above has a breakdown of several ENVE wheels. The top-end SES 7.8 remains the fastest in their lineup, but the new Foundation 65 is not far behind. ENVE noted that all wheels used an identical 25mm tire, and testing was performed at the Mercedes F1 tunnel in the UK. Testing was done with a bike (a new Scott Foil), but no rider, at 20 and 30mph speeds.

The topic of wheel stability also came up in my conversations with ENVE. Wheels with better stability cause less steering input when you catch a gust of wind from the side. This issue is separate from side force, which is the amount of lateral ‘push’ you feel, irrespective of any steering input caused. The Foundation series wheels don’t quite match the stability of the premier SES rims due to differences in rim shape, but ENVE claims performance above competitors in the same price range.

Setup and Riding

I recently took delivery of a pair of Foundation 65s, with the hopes of getting some miles on as soon as possible. I opted for the deeper rims because, heck – you’re triathletes, aren’t you – and I figured the more aero-focused product would be of interest.

The rims have a 28mm outer width and a 21mm internal width. This makes them wider than the comparable SES 5.6 (19-20mm internal width), but not as wide as the All Road-focused AR 4.5 (25mm internal width). ENVE specifies a minimum tire width of 25mm.

It’s worth noting that, like the AR series wheels, the new Foundation series uses hookless rims. This eases production on the factory-level, due to the style of mold used.

The hookless design means that ENVE ONLY allows the use of tubeless tires. They take it one step further and say that you must use a tire that’s on their approved list, to ensure compatibility and safety. We took a tour of their test lab last year to learn more about this topic, and the striking differences between the measurements of various tires on the market. Tire bead stiffness and diameter are all over the map, and some tires don’t make the cut. If the tire beads are too large in diameter, or not sufficiently stiff, they can blow off a rim that doesn’t have the additional failsafe of bead hooks.

ENVE’s position is that all other tubeless tires use hookless rims (i.e. automotive, industrial, etc), and bicycles should follow suit, to enjoy potential benefits in weight and strength, along with lowered rim manufacturing costs. The other big bonus is that's easier to manufacture a more precise bead seat diameter of the rim, aiding in tubeless setup.

The problem is that bicycles don’t currently have sufficient tire testing standards to ensure safety with hookless road rims – so ENVE took it upon themselves to test every tire they can get their hands on. The list of approved tires can be found at ENVE’s website.

You might be wondering – does the hookless design mean that this is an allroad or gravel wheel? I asked this exact question to ENVE. Their answer was… “Not exactly.” In a way, it’s kind of like a narrower version of the AR rims. Used with an appropriate tire, the Foundation wheels can certainly be used for rough roads or light gravel roads. However, they’re not purpose-built for this, and their AR or G-series wheels are a better choice if you’re focusing on those surfaces. My take is that the Foundation wheels weren’t made so much to hit a specific use case as they were made to hit a specific price point.

My wheels came with tubeless tape and valves, and I headed to my garage to get them ready. I used a new set of tires that’s unfortunately not public information yet, but they are tubeless-specific, ENVE-approved, and made by a manufacturer well-schooled in tubeless tire technology. I have successfully set up a LOT of different tubeless wheels and tires, so this was business-as-usual for me.

To make a long story short (which is somewhat hampered by the fact that I can’t talk about the tires yet), the inflation of one wheel was perfect, and the other was not. It required multiple tape installations, half a jug of sealant, and a fistful of CO2 cartridges. What I can tell you is that it’s imperative that you clean the rims thoroughly with rubbing alcohol before tape application (which I always do), and that you do not skip the step of installing an inner tube to each tire and pumping it up overnight. Adding a tube helps to smash down the rim tape, ensuring full adhesion. Also be sure that the section of tape overlap occurs at the valve area, building up the surface on which the valve will sit (this is ENVE-specific, as some manufacturers suggest you leave this overlap area on the other side of the rim). I tell people to treat the initial setup of tubeless wheels and tires like we treated tubular tires – as a multi-day procedure.

As it stands, I still have one wheel that holds air perfectly, and one that goes flat after about a day. We are still working to troubleshoot this (i.e. Is it a wheel issue? A tire issue?), and will post an update as we reach resolution. In the meantime, I’m throwing a latex tube into the existing tire to get back out on the road.

[Update: After investigating many possibilities, we have narrowed this down to an issue with the tire. I swapped to a tubeless 25mm Schwalbe Pro One, which is successfully holding air for extended periods. -Ed]

I mounted the Foundations up to my loaner rig from Cannondale – a Topstone alloy gravel bike. But… these aren’t gravel wheels! True, but this is the bike I have available to me, and it actually works quite well as a road bike.

Once I started pedaling, it was immediately apparent that these wheels are fast. The tires inflated to 27mm wide, so I opted for 80psi (I weigh about 195 lbs currently). The wheels were so fast that I quickly realized that my gravel bike did have an issue – limited gearing. I found myself quickly climbing the cassette and into the 46x11 top gear while cruising with a moderate cross/tailwind on a flat road. I don’t have a power measuring device on the bike for exact figures, but I completed my 20-mile local loop about ten minutes faster than on my recent test wheels - some 650b gravel hoops with wide tires. The speed and feel of the bike was strikingly different. As it stands, the Foundation 65s are so good in the speed department that I’d have a hard time telling someone to spend the extra bucks on an SES wheel, unless they were convinced that they didn’t want to run tubeless (the standard SES wheels feature bead hooks and less stringent tire requirements).

Product launches often come together last-minute, and I’ve only had a chance to ride these wheels once. It was a promising first ride, and I look forward to more miles (and may need to find myself a bigger chainring).

The Foundation 45 and Foundation 65 are available now for $1,600 USD per pair. They include a five-year warranty and Lifetime Incident Protection. Learn more at ENVE.com.