It’s not often that we get a two-for-one deal here at Slowtwitch, but today we have the privilege of checking out the DT Swiss headquarters in Biel, Switzerland – with an extra bonus that it’s being done alongside draft-legal phenom, Richard Murray. Murray is sponsored by DT Swiss and recently got the full download on their production, testing, and technology.

“My visit to DT Swiss was something epic, seeing how the wheels are built was something I’ve always wanted to see,” recalled Murray. “The spokes are made from large spools of wire in-house, along with where my wheels are hand built by 10 people working full time… [they] do not hold back on the fine detail. The logos are hand applied by water transfer, [and every wheel is] tested and spoke tension checked…[it] was very cool.”

The facility consists of two main parts - the wheel building area, or BPM (Biel Performance Manufacturing), and the Performance Test Center. The majority of DT Swiss wheel building is done in Poland, with the BPM available for special needs and extra capacity for high-demand parts of the year.

DT reports that their sales are about 55% mountain bike (including E-MTB) and 45% road (including gravel). They didn’t officially sell gravel-specific products until 2019, so more exact numbers aren’t yet available. Prior to this, their Endurance Range and CX products took care of gravel needs for DT customers.

Richard travels with only one set of wheels at a time, swapping clincher tires for training (Vittoria Rubino Pro) and racing (Vittoria Open Corsa). He uses either the ARC 1100 DICUT 48 or PRC 1100 DICUT 35, depending on course profile.

Which is better for doing wheelies? That we don’t know.

Richard closely inspects spoke production. DT reports that an 800kg wire roll can produce 115,000 spokes.

Finished spokes come out in all shapes and sizes for different wheel applications – butted, bladed, or round.

Richard even tries his hand at lacing up a wheel – no easy feat for a beginner.

DT Swiss has 29 engineers on site, many of whom commute to work or take part in lunch rides.

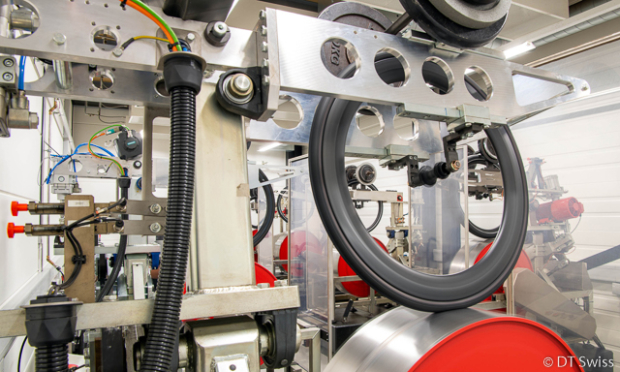

The Performance Test Center is where all of the action happens, putting wheels through a rigorous series of tests to ensure quality and safety.

Drum machines test things like drive stiffness by putting force through the freehub to see how forces transmit to the hub and spoke system.

We don’t know if DT Swiss does any rolling resistance (Crr) tests here, but we can only hope.

In keeping with Swiss tradition, the test center appears to be very clean and orderly.

In addition to lab testing, DT reports that their factory test team has completed over 213,000km of test riding in the last three years.

Richard leaves his sponsor with a personalized wheel as a reminder of his visit.

Richard is chasing gold at the 2020 Games in Tokyo, and looks to be off to a good start in his preparation.